Introduction

Model Description

Problem Definition

Analytical Solution for Stresses and Displacement in the Plastic Region

Comparison of Solutions

Perfect-Plastic Medium

Elastic-Brittle-Plastic Medium

Conclusions

Introduction

Symmetrical circular tunnels are widely considered in geotechnical engineering, and many closed-form solutions and numerical methods have been developed for design of their support systems (Detournay, 1986; Wang, 1996; Carranza-Torres and Fairhurst, 1999; Egger, 2000; Alonso et al., 2003; Wang et al., 2010; Osman and Randolph, 2011; Zareifard and Fahimifar, 2014; Fahimifar et al., 2015; Zhao et al., 2016; Katebian and Molladavoodi, 2017). Many studies have focused on analytical solutions for a circular underground opening in brittle-plastic rock mass governed by the linear Mohr-Coulomb (M-C) and the nonlinear Hoek-Brown (H-B) failure criteria. Brown et al. (1983) reviewed previous work, and developed a closed-form solution for an elastic-brittle-plastic H-B medium and a numerical solution for a strain-softening H-B medium. Ogawa and Lo (1987) derived an analytical solution and analyzed the effects of dilatancy and yield criteria on the displacement and stress around tunnels. Sharan (2003, 2005) presented closed-form solutions for elastic-brittle-plastic H-B rock. Park and Kim (2006) derived a closed-form solution for a circular tunnel in a brittle-plastic rock mass governed by the H-B yield criterion, and compared the displacement in the plastic zone under different elastic strain conditions.

However, these previous solutions consider 2D failure criteria, which neglect the effect of the intermediate principal stress () on the strength parameter and displacement of the surrounding rocks under excavation. To address these issues, this work considers the effect of the intermediate principal stress for an elastic-brittle-plastic medium. The extended spatially mobilized plane (SMP) is employed for frictional and cohesive materials in 3D stress space (termed ‘extended SMP’) (Nakai and Matsuoka, 1983; Matsuoka and Sun, 1995). This paper presents an analytical solution for circular tunnel excavation in brittle-plastic M-C and extended SMP media considering the effect of the intermediate principal stress. The solution was transformed from brittle-plastic solutions to perfect-plastic solutions when setting the residual strength parameters equal to the peak values. Comparison of the displacements and stresses of the solutions with the Kastner solution indicates that brittle-plastic behavior of rock mass greatly extends the plastic zone and the displacements around the cavity due to the effect of the intermediate principal stress. Ground response curves are produced for both M-C and extended SMP criteria, and the effects of the intermediate principal stress on cavity wall convergence and the plastic radius are discussed.

Model Description

Problem Definition

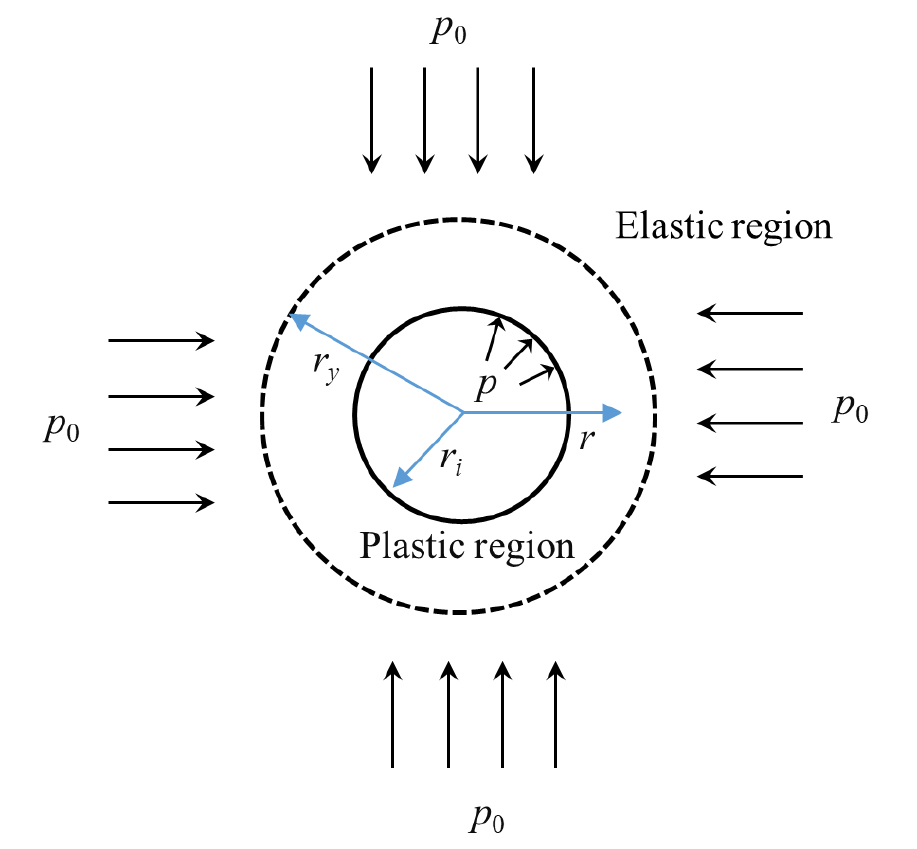

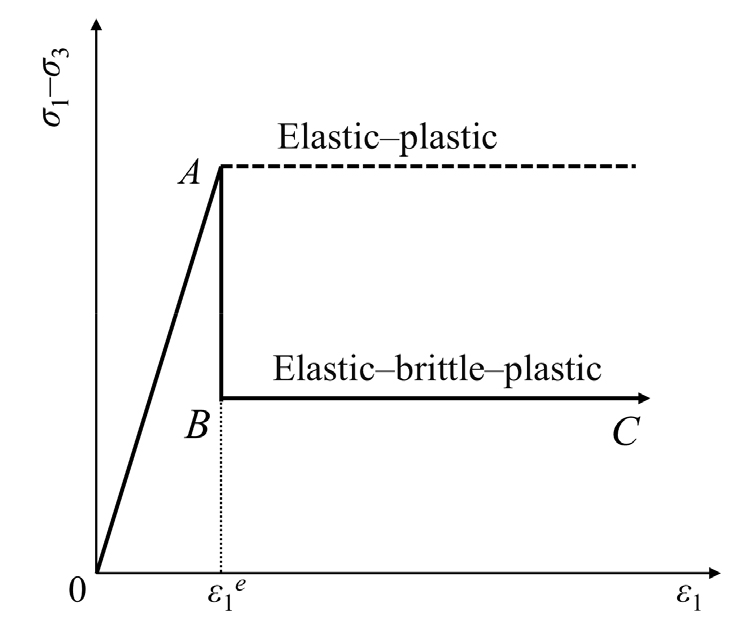

Fig. 1 shows a circular tunnel being excavated in an initially elastic rock mass subjected to a hydrostatic stress . The tunnel surface is subjected to an internal pressure . A plastic region develops around the opening when p reaches the yield stress. Upon yielding, the rock’s strength suddenly drops, and it then follows post-yield mechanical behavior as shown in Fig. 2. The H-B and M-C criteria are the most commonly used strength criteria for rock masses, both of which neglect the effect of the intermediate principal stress on the stress and displacement of the elastic and plastic regions. The extended SMP failure criterion, which considers the effect of the intermediate principal stress , is adopted here to solve the stresses and displacements in the plastic region.

The extension of SMP for cohesive and frictional materials by Matsuoka and Sun (1995) and Nakai and Matsuoka (1983) defined the extended SMP failure criterion as follows:

where, and are normal stress and shear stress in extended SMP failure criterion, and , , and are the principal stresses for a cohesive material, and are given as

where, , and and are the cohesion and friction angle of the material, respectively.

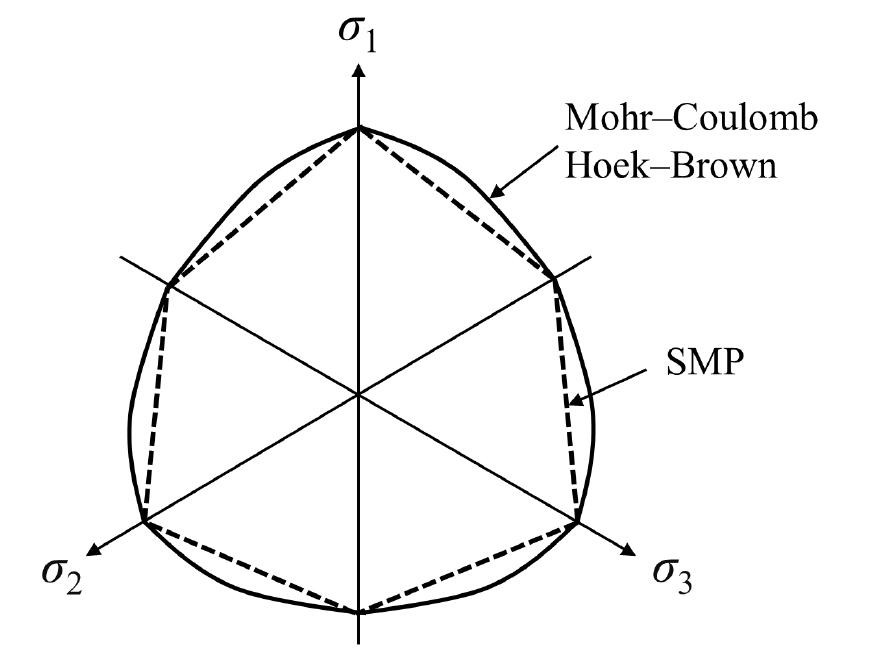

Expressing the condition on the octahedral plane yields the SMP results as a smooth curve representing the Mohr-Coulomb criterion (solid line in Fig. 3) circumscribing a hexagon (dashed lines in Fig. 3). For a cohesive material, the extended SMP failure criterion for a planar strain state can be obtained based on the following equation:

The axial symmetry of the problem leads to the radial stress and tangential stress in the rock mass being the principal stresses, such that and .

For a planar strain problem, Eq. (1) is rewritten as follows:

(i) in an elastic-plastic medium

(ii) in an elastic-brittle medium (Fig. 2)

where, ; ; ; ; ; and . and represent the ratio of major stress to minor stress at the peak strength and residual strength, respectively. and are the friction angle of the initial and residual states, respectively, under triaxial compressive stress (Fig. 3).

Analytical Solution for Stresses and Displacement in the Plastic Region

Critical Internal Pressure

Lamé’s solutions for the elastic region are as follows (Fig. 1):

An unsupported opening starts to fail when the in situ stress exceeds the critical pressure . By assuming that the plastic zone reaches the wall of the opening, the critical internal pressure is found by substituting Eq. (6) with in Eq. (4):

For an opening with a supporting system (supporting force, ), when exceeds , the minimum value of can be solved for the surroundings of the opening with no plastic zone:

Stresses in the Plastic Region

Substituting the equilibrium equation in Eq. (5) obtains the stress in the plastic region for the extended SMP failure criterion:

Based on equation (10), the tangential stress on the elastic-plastic boundary is

Replacing and with and in Eq. (6) yields the stress in the plastic region:

Substituting Eq. (12) with in Eq. (4), we obtain . Considering the radial stress continuity at the elastic-plastic boundary, the plastic radius is

For no stress-drop or strain-softening, the radius of the plastic region can be found by replacing and with and :

Displacement in the Plastic Region

According to classical plasticity theory, the total strain consists of elastic and plastic parts. For planar strain, neglecting volumetric strain, the relationship between the radial and tangential strains is

From the condition of compatibility in the case of infinitesimal deformation, the displacement at the elastic-plastic boundary is

The displacement at the opening wall is

The closed-form solution for the perfectly elastic-plastic problem can be obtained by replacing and with and , respectively.

Comparison of Solutions

As rocks are strain-softening materials exhibiting peak and residual strength, it is reasonable to assume that they obey elastic-brittle-plastic behavior given that the mechanical parameters are accurate. Therefore, the effects of the strength parameters and internal pressure on the convergence of the opening wall and the plastic radius in the brittle-plastic extended SMP rock mass are assessed by comparing the presented solution with the Kastner solution (based on the M-C failure criterion) in both perfect-plastic and brittle-plastic media. Table 1 lists the geometric and mechanical parameters for three cases with different residual cohesions.

Table 1.

Geometric and mechanical parameters

The failure stress and critical support pressure in M-C and extended SMP media can be obtained using Eqs. (8) and (9). The failure stress (11.8 MPa) in the extended SMP medium is larger than that in the M-C medium (9.4 MPa). The critical support pressure (9.5 MPa) in the extended SMP medium is smaller than that in the M-C medium (11.8 MPa). The result implies that strengthens the opening wall in the extended SMP medium.

Perfect-Plastic Medium

Effect of Internal Cohesion and Friction Angle on the Plastic Radius

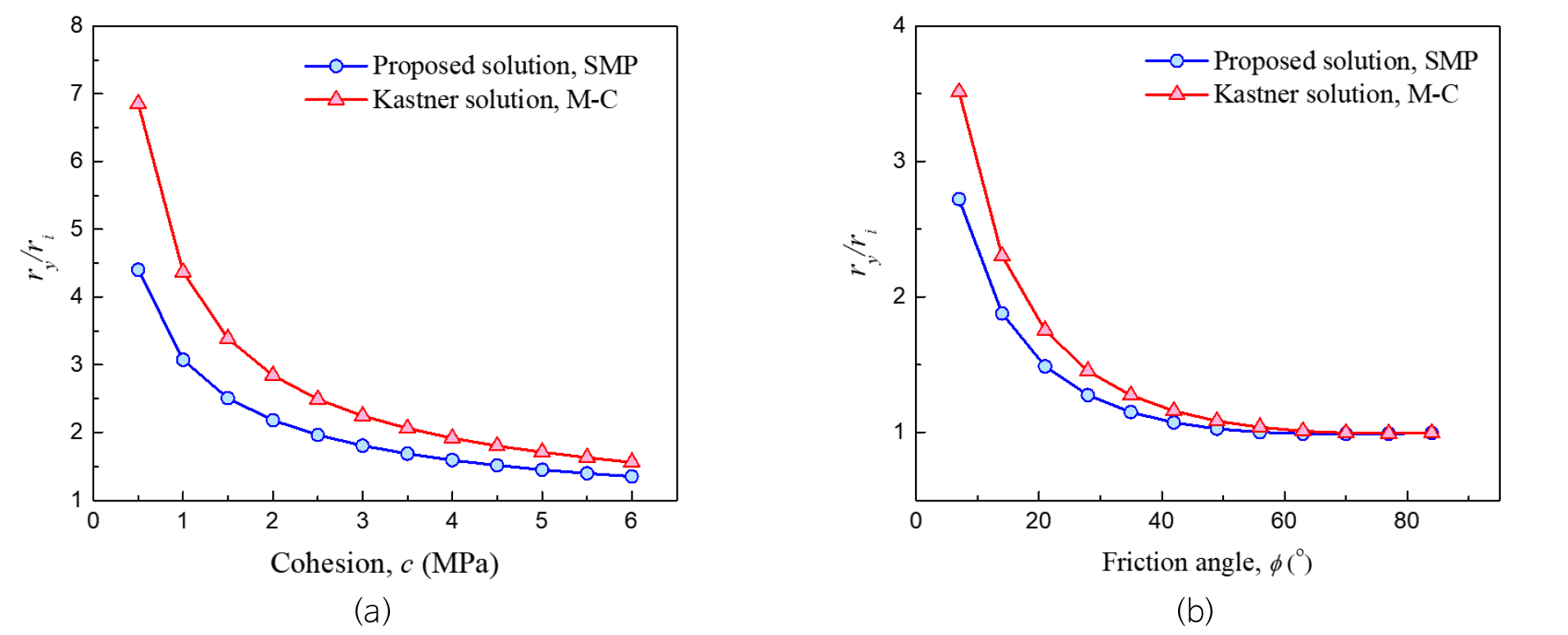

Fig. 4a shows the effect of internal cohesion on the dimensionless plastic radii in M-C and extended SMP media. The dimensionless plastic radius is the ratio of the plastic radius to the initial tunnel radius (). For c > 3 MPa, a variation in c has a slight effect on the dimensionless plastic radius. In contrast, for c < 2 MPa, any variation in c has a strong effect on . The ratio in the extended SMP medium is smaller than that in the M-C medium by 12.8% for c = 6 MPa and by 29.6% for c = 1 MPa.

Fig. 4b shows the effect of friction angle on the dimensionless plastic radii in the M-C and extended SMP media. The trends are similar in both media. For 20° < 𝜙 < 30°, the variation in 𝜙 has a slight effect on the ratio. In contrast, when 𝜙 < 20°, is strongly affected by any variation in 𝜙.

Effect of on Displacement and Stress in the Plastic Region

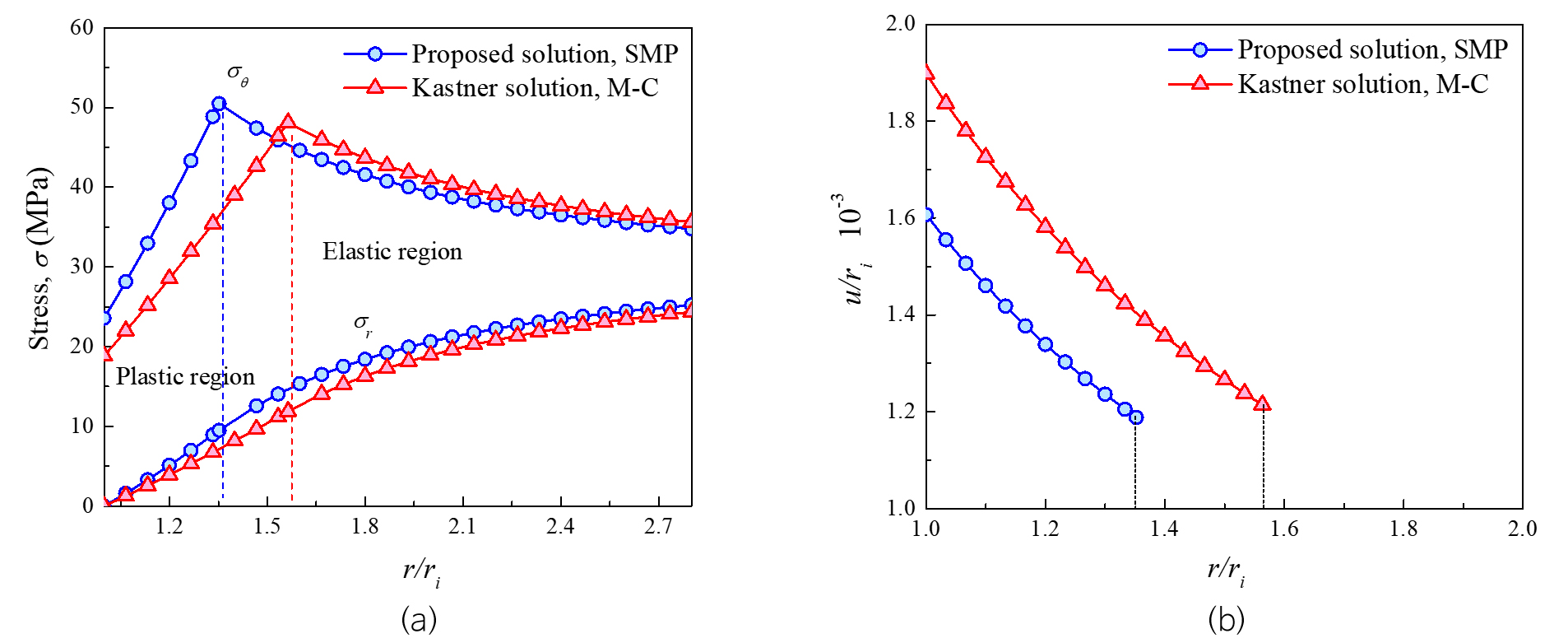

Fig. 5a shows the stresses in the M-C and extended SMP media, in the case of (30 MPa) > and . The hoop stress of the opening wall in the M-C medium (23.5 MPa) is larger than that in the extended SMP medium (18.8 MPa). The maximum value of (50.5 MPa) at the elastic-plastic boundary is larger than (48.2 MPa). The plastic radius (4.1 m) is smaller than (4.7 m). The radial stress in the plastic region is larger than , which implies that the rock is strengthened by .

Fig. 5b shows the displacement in the plastic region. The plastic radius in the extended SMP medium is 15.6% smaller than . The convergence displacement of the opening wall in the extended SMP medium is 18.7% larger than that in M-C medium .

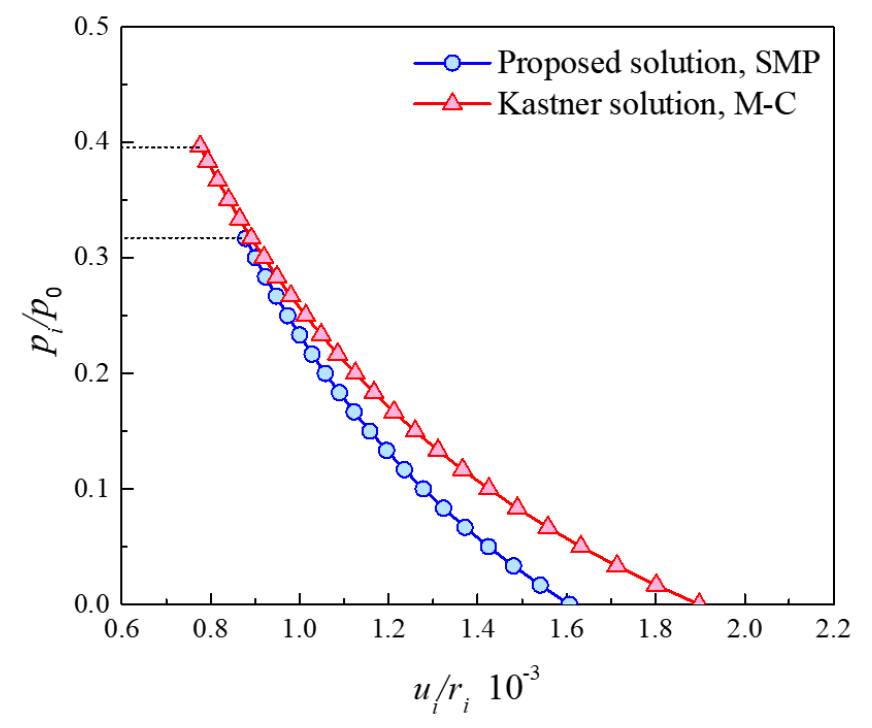

Fig. 6 shows the ground reaction curves in M-C and extended SMP perfect-plastic rock masses. The supporting force is decreased due to the presence of .

Elastic-Brittle-Plastic Medium

Effect of on Stress, Plastic Radii, and Ground Reaction Curves

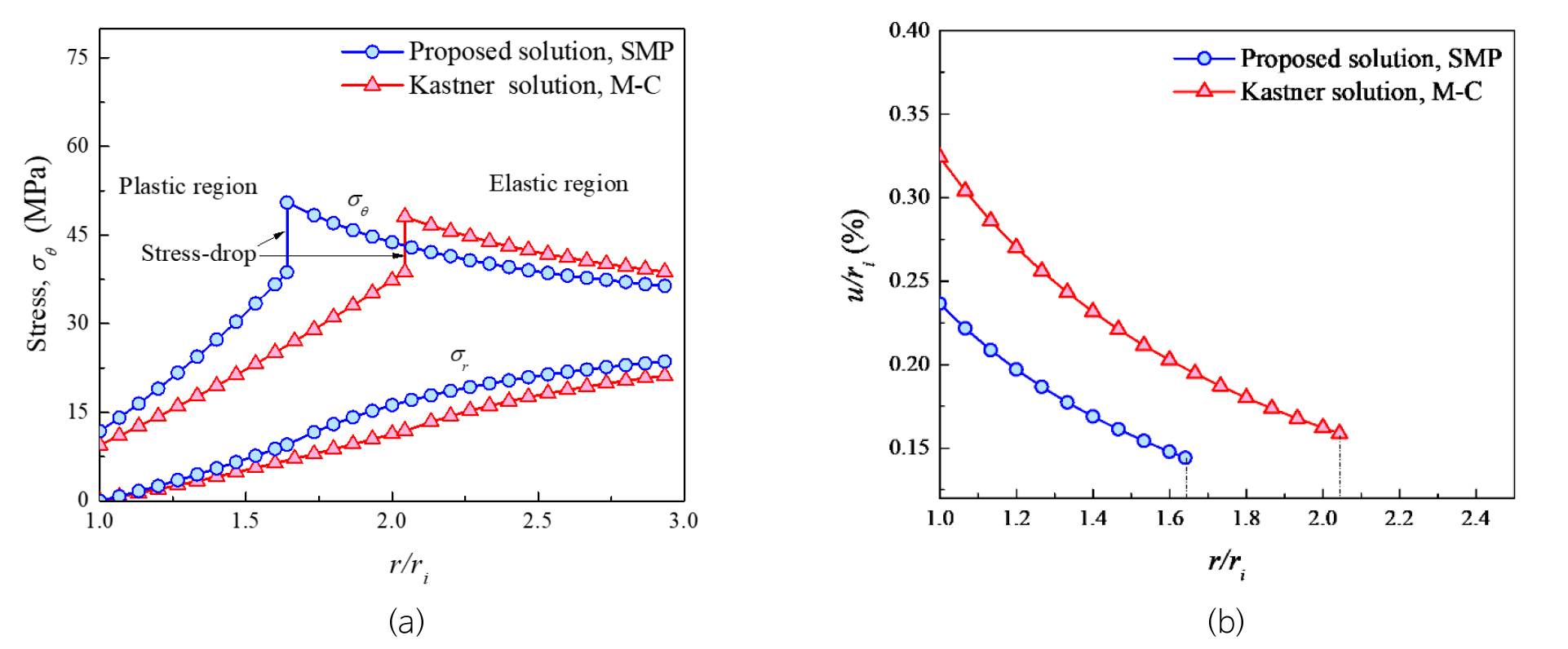

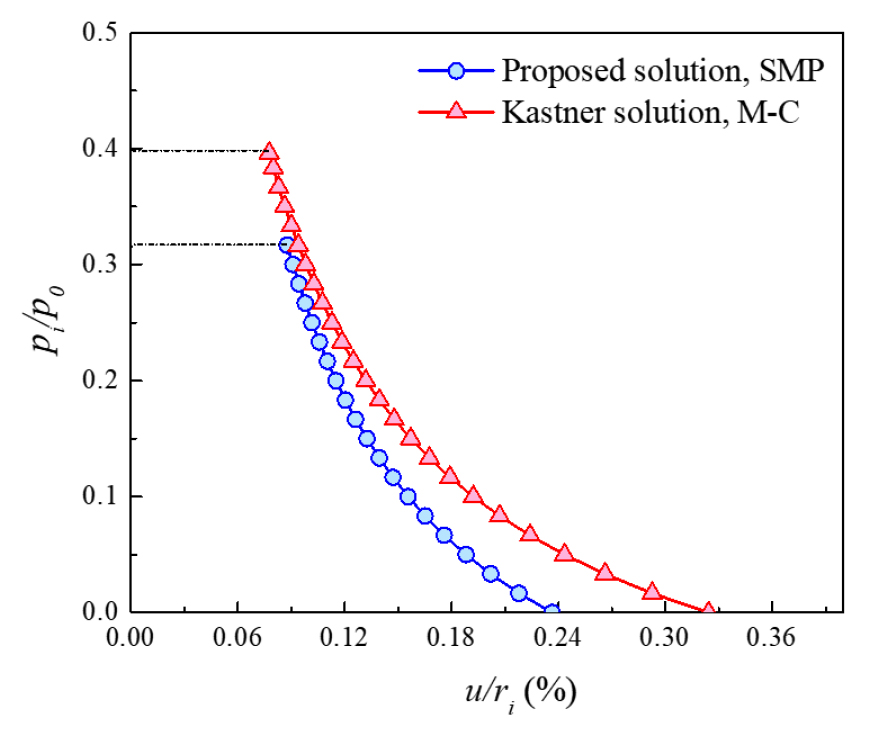

Table 1 lists the residual strength parameters for a brittle-plastic medium. Fig. 7a shows the stress and displacement in the plastic region. The plastic radius (4.9 m) in the extended SMP medium is smaller than (6.1 m). The convergence displacement of the opening wall (4.8 mm) in the extended SMP medium is 18.7% smaller than that in the M-C medium (5.7 mm). The radial stress in the plastic region is larger than . The hoop stress of the opening wall in the extended SMP medium (11.7 MPa) is larger than that in the M-C medium (9.4 MPa). The maximum value of (50.5 MPa) at the elastic-plastic boundary is larger than (48.2 MPa). These results suggest that the rock strength increases with increasing . Fig. 7b shows that the plastic radius (4.9 m) is 24.6% smaller than (6.13 m) and that (7.1 mm) in the extended SMP medium is 37.3% smaller than that in the M-C medium (9.7 mm). Fig. 8 shows that the supporting force () in the extended SMP medium is smaller than that in the M-C medium, and the dimensionless convergence displacement () in the extended SMP medium is also smaller than that in the M-C medium. These results indicate that the rock strength is significantly affected by .

Effect of Strength Reduction on Plastic Radius and Opening Wall Convergence

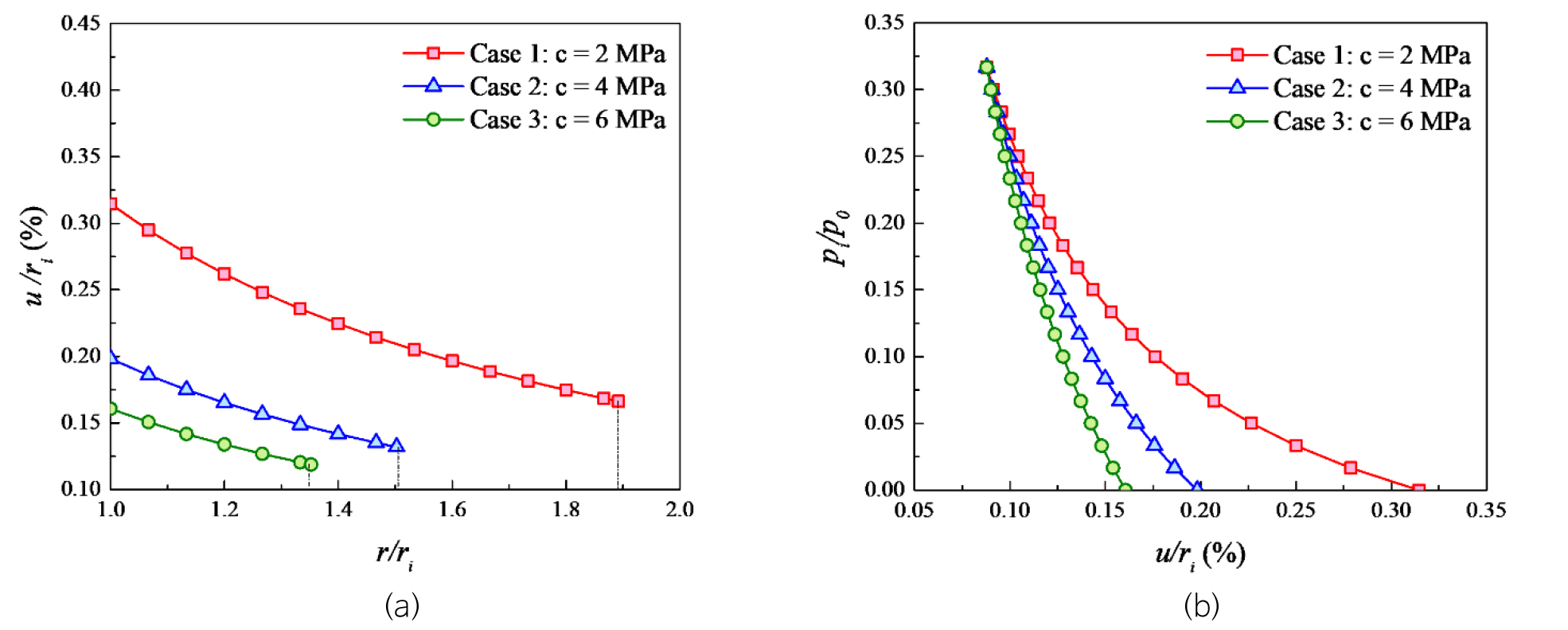

Fig. 9a shows the effects of residual cohesion on the dimensionless radial displacement of the opening (). The plastic radius increases by 24% as the residual cohesion decreases from 6 to 2 MPa. In addition, the critical supporting force () was not affected by the reduction in residual cohesion (Fig. 9b). The displacement of the plastic region increases by 100% as the residual cohesion is reduced from 6 to 2 MPa.

Conclusions

To estimate the effects of the intermediate principal stress on the plastic zone and the convergence of circular excavation in an elastic-brittle-plastic medium, closed-form solutions for both M-C and extended SMP media are presented for stresses and displacements in the plastic region.

The results for displacements and stresses are compared with the Kastner solution. The plastic radius and displacement obtained for an extended SMP medium increase significantly compared with those obtained for an M-C medium. The solutions can be used to investigate the effects of internal pressure on the convergence of opening and the extent of the plastic region in a brittle-plastic medium. The strength in the residual plastic region is higher in the extended SMP medium than in the M-C medium. For a decreasing residual strength of the rock mass, the opening wall convergence increases sharply when the residual cohesion decreases substantially from 6 to 2 MPa. This means that the stability of the underground opening is enhanced by the intermediate principal stress and the critical supporting pressure is decreased, which reduces the cost of the supporting system.